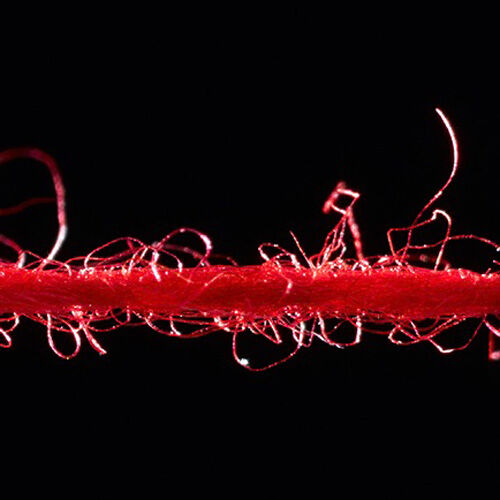

Our yarn manufacturing partner originally came from the mechanical engineering sector where they developed and built machinery − and that same inventive spirit still pervades the company. So it comes as no surprise to learn that, back in the 1950s, they were the ones with the ground-breaking idea of using 2/28 yarn, now a seal of quality in the world of cashmere. To this day, this exceptional quality of two-ply yarn is only produced by an elite circle of manufacturers. Keen to stay ahead of the field, our yarn manufacturing partner is constantly refining the machinery on the shopfloor so as to produce yarns of ever higher quality. Understandably, this leads to a certain reticence on the part of the owner when it comes to visiting the factory.

These mechanical refinements are well-kept trade secrets. In recent years, the company has sharpened its focus on sustainability, leading to collaboration with Greenpeace as part of the Detox project. Here, manufacturers commit to full transparency regarding all substances employed in their production and dyeing processes and undertake to work towards permanently reducing the use of harmful substances. Added to which, at the “Pitti Filati” show, the company also presented the first ever completely natural cashmere capsule collection – made entirely without additional colorants or toxic agents.